The regular clicking noise is the cams staying still and the chain clicking over the top of the teeth, instead of turning the sprockets.Yorkie boy wrote:Well......it was all going smoothly. Link provided by Cybercarl made it all fairly straight forward and stripped everything down with no problems. However, when turning the crankshaft end bolt ahead of removing the ccts it feels like it's locked out. the first few turns were accompanied by a regular clicking noise and then nothing but a lot of resistance. Listening to Cybercarl's advice I haven't forced it but I'm stuck with how to sort the timing and get TDC.

Any suggestions on how best to proceed would be well received - kettle on, garage door shut (for now) !!

Stu

This can only happen when a cct has failed.

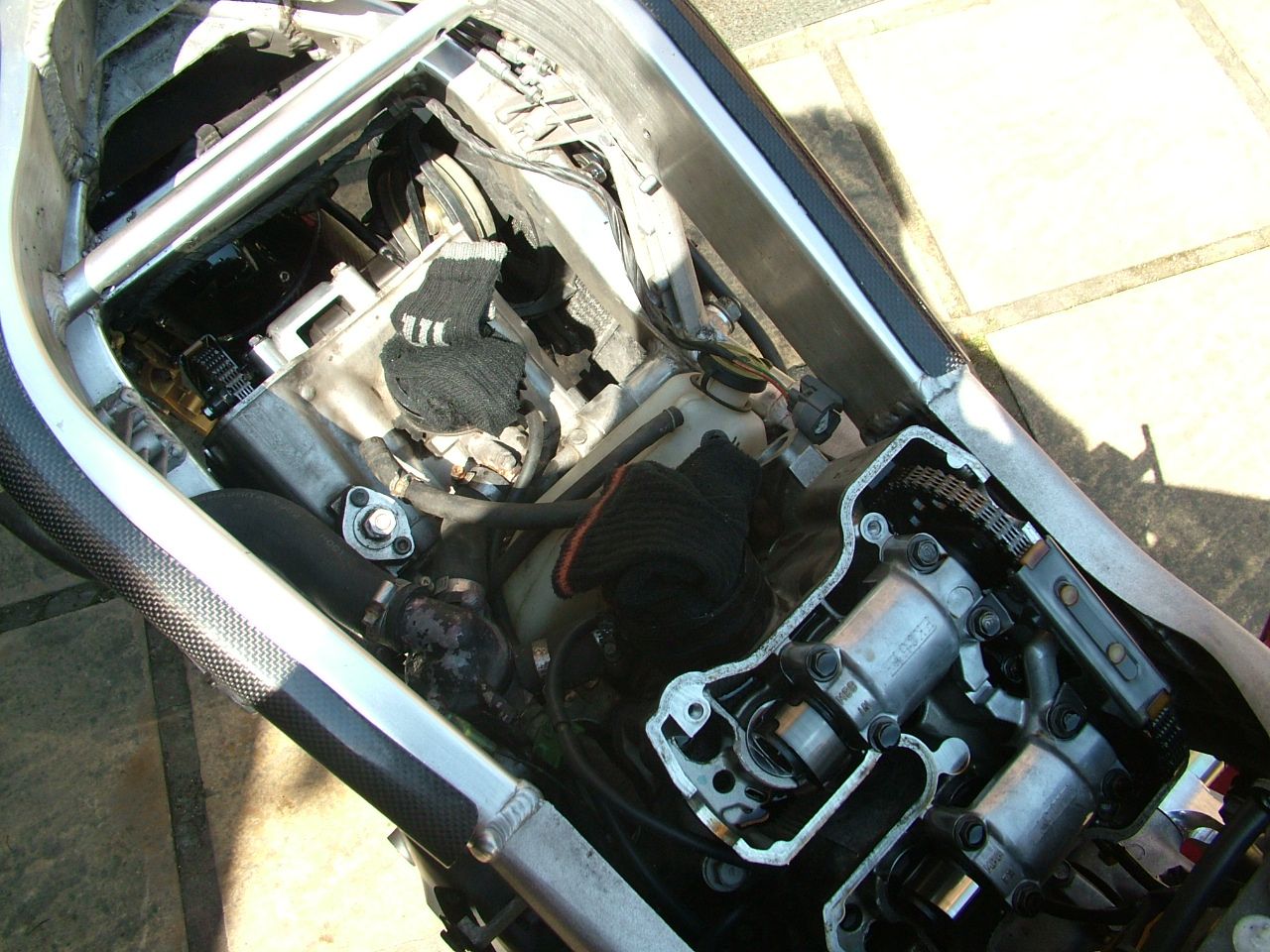

It's not a disaster, don't turn the engine any more until the cams and cct are removed entirely on the affected head.

I'll most likely be the front cylinder.

Have a good read of Sirch's guide in the Workshop sticky section regarding how to fit manual cct's.

You will see that you can start the process with either cylinder in the correct top dead centre position.

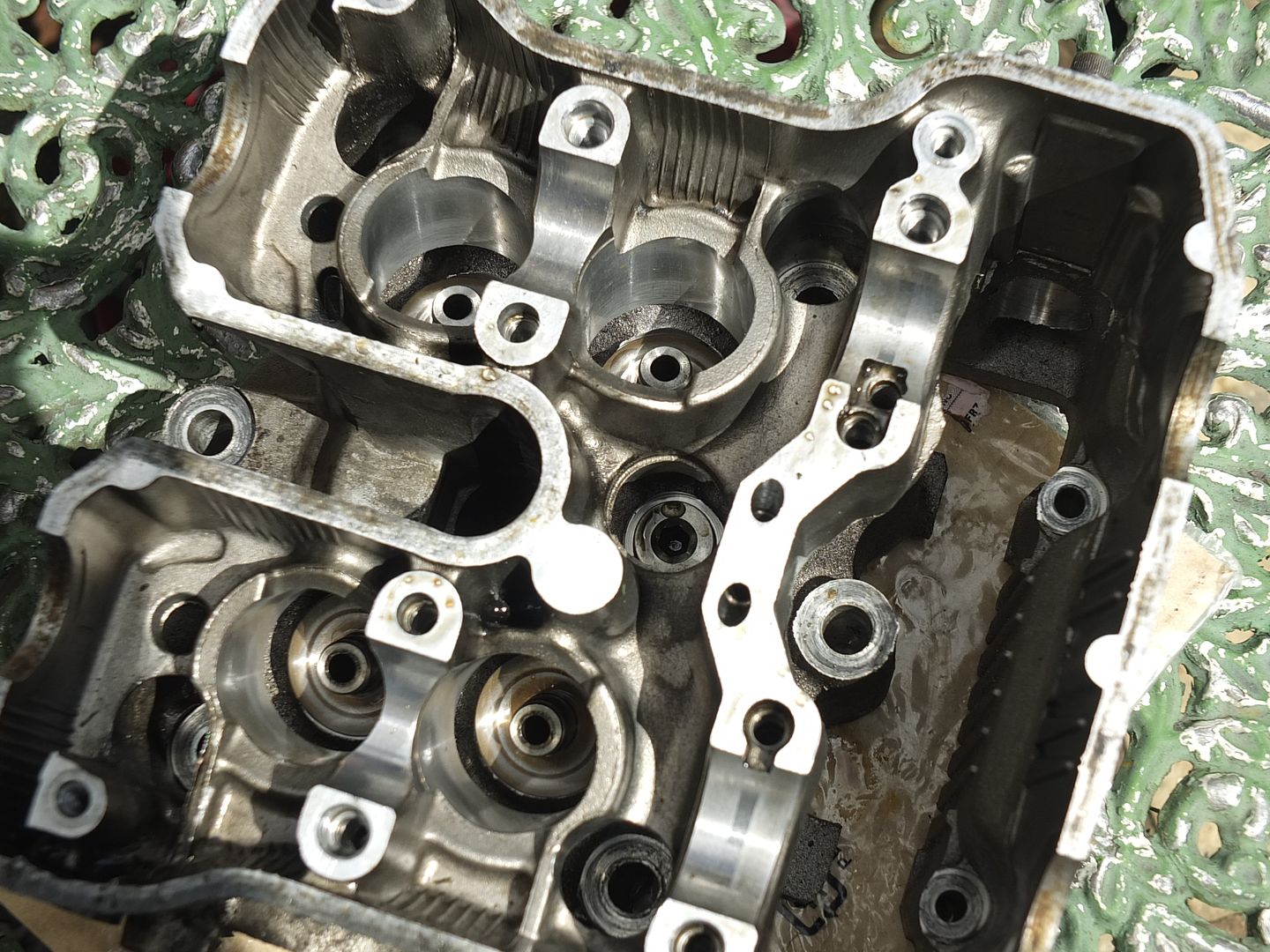

Assuming that I'm right and it';s the front one that's failed, once you have removed the front cams, and hooked the chain over a screwdriver sitting where one of the cams normally goes (to stop the chain snagging around the crankshaft when you turn it), you set the engine to the correct REAR tc (cams pointing upwards and towards each other). You won't have to remove the rear cams.

From that point, rotate the engine one and a quarter turns anticlockwise, and reinstall the front cams so that the lines on the sprockets line up with the top surface of the head, as near as it can be, anyway.

Don't forget to apply tension to the chain run on the tensioner side, even though it isn't there or working.

At this point you can choose to fit manual ccts, another set of standard Honda ones and take a chance when they fail again (not recommended) or fit a pair of new Honda ones and carry out the stopper modification to them.

Don't try to turn the engine over again without some sort of working CCT in it...

Once all that's done, you can then check valve clearances to see if you have bent any valves- normal clearances are in Haynes but anything over .5mm means that you have bent valves.